Atmospheric Pressure Plasma

Targeted functional coatings

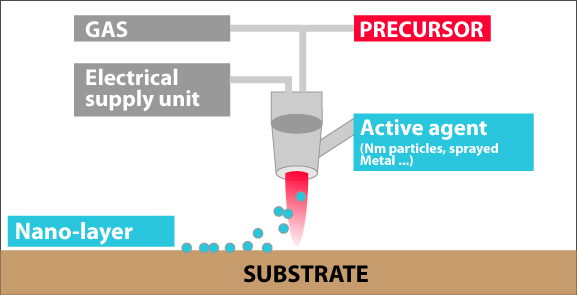

Atmospheric Pressure Plasma has been established for surface pre-treatment particularly in the area of plastic processing for many years. However, plasma discharges at atmospheric pressure can not only activate but also specifically functionalise the surfaces of different materials.

The gas will first be continually injected into the plasma generator, where it will be ionised and finally directed onto the surface to be treated. Gas molecules divide into charged particles, ions and free electrons. These particles deposit on the surface to be treated and create modified connection opportunities e.g. for varnishes and paints.

To realise specific functional coatings, the gas can be enriched with a suitable precursor.

Coating Properties

- Film thickness up to 200 nm

- Transparent and flexible coating

- Scratch-resistant

- Creation of a defined wettability: from hydrophilic to hydrophobic

Process Properties

- Suitable materials : plastics and elastomers, glass and ceramics, metals, natural materials such as wood, textiles, filaments, 3D-geometries

- High process speed

- Easily integrated into automated production processes

Applications

- Adhesion-promotion for paints, inks and glues

- Transmission-improvement for coatings

- Corrosion protection coatings

- Barrier layers (alkali barrier layer on glass, gas permeation barrier layer on plastics)

- Adjustment of the surface energy from hydrophilic to hydrophobic

- Bactericidal coating

We will gladly advise you. Please contact us.

Contact person:

Dr. Arnd Schimanski

Phone: +49(0)3641 20 49 80

Mail: schimanski(at)sura-instruments.de