PYROSIL® Process

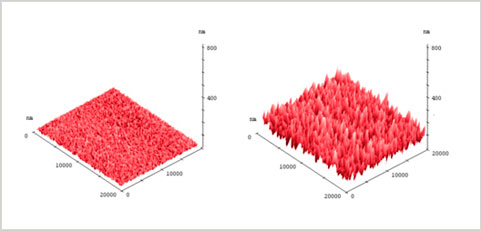

Creating a nanoscale-roughness

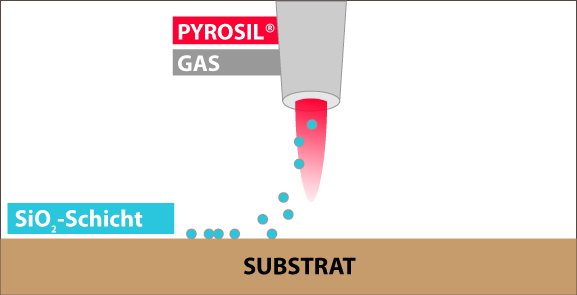

The PYROSIL® Process is based on the flame-pyrolytic deposition of amorphous silicon dioxide on a substrate material, and thus a type of silicate coating. The surface to be treated will be fed through a gas flame which is doped with a silicon-containing precursor material (PYROSIL®). The PYROSIL®, also referred to as the precursor, burns in the flame and deposits on the surface in a very thin but dense and firmly adhering silicon oxide coating (5 – 100 nm). Due to the short flame-substrate interaction the material’s surface temperature remains moderate. Thus, the PYROSIL® Process is suitable not only for glass, ceramics or metals but also outstanding for plastics.

Structured, strongly enlarged surfaces with improved chemical bonding opportunities can be treated effectively and cost-efficiently with the PYROSIL® Process.

Coating Properties

- Roughening (nano-porous) of the material surface

- Hydrophilisation of the surface, very high surface energy

- Invisible and flexible coating

- Realization of a well-defined and highly reactive surface

- Long-term stable coating (in combination with a primer, it can be stored without activation loss for 1 – 4 weeks before further processing

Process Properties

- Effective and cost-efficient scalable process

- Low temperature protects material

- Can be used for nearly any materials

- Parameters can be customised for customer requirements

Applications

- Adhesion promotion layer for varnishes and glues

- Corrosion protection layers

- Sealing layers

- Barrier coatings

We will gladly advise you. Please contact us.

Contact person:

Dr. Norbert Eckardt

Phone: +49(0)3641 20 49 8-27

Mail: eckardt(at)sura-instruments.de